Relied On Packaging Machine Repair Service for Long-Lasting Tools Efficiency

Relied On Packaging Machine Repair Service for Long-Lasting Tools Efficiency

Blog Article

Comprehensive Guide to Effective Packaging Machine Repair Work Methods for Optimum Efficiency

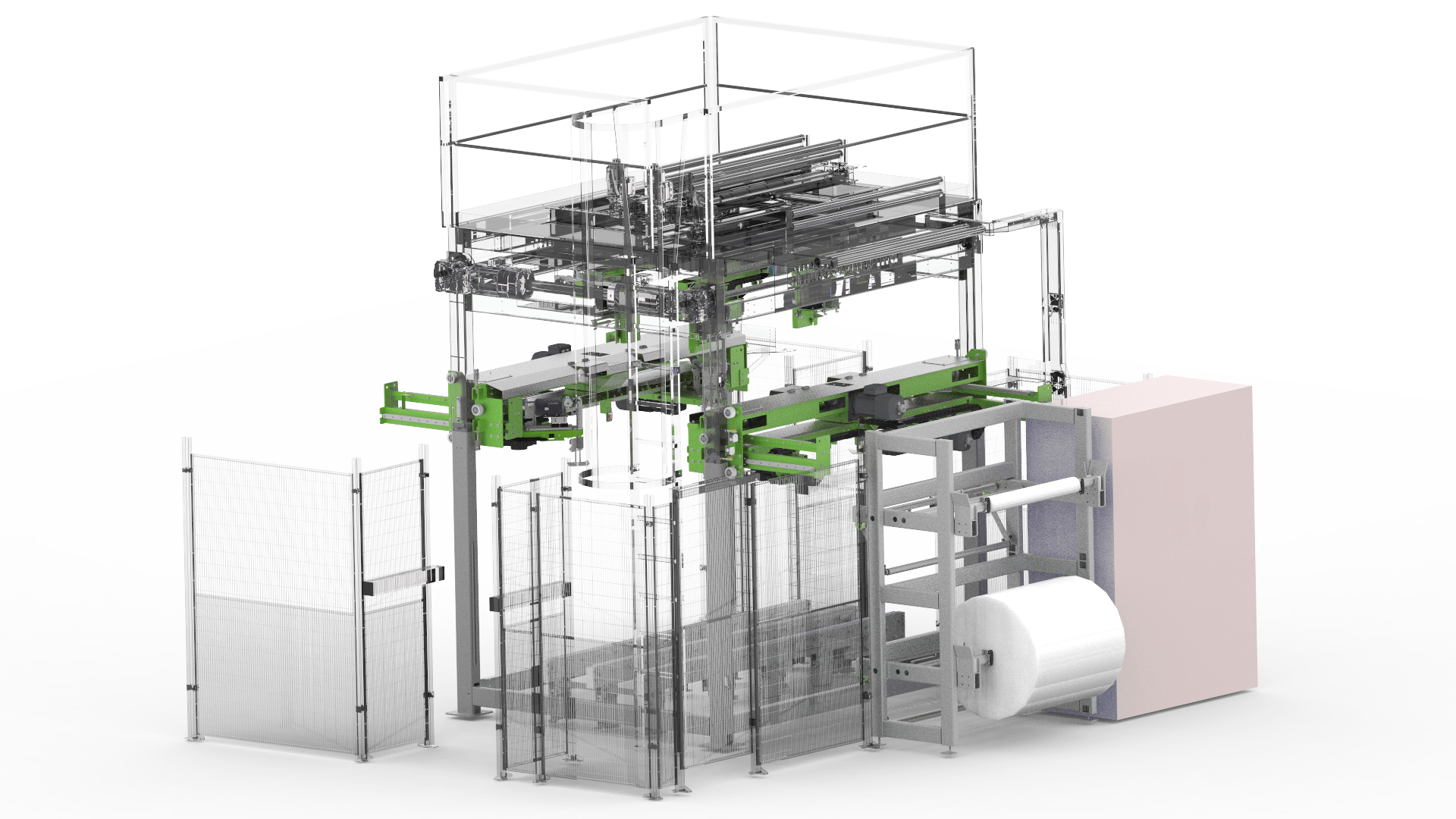

Efficient product packaging equipment repair work is critical for preserving functional continuity and item quality in today's busy production environment. Employing a structured technique to diagnostics and repair service, together with preventive upkeep techniques, can dramatically boost maker longevity and efficiency.

Common Product Packaging Maker Concerns

Packaging machines, essential for effective manufacturing lines, typically experience numerous usual issues that can interrupt operations. One common issue is imbalance, which can cause improper securing or labeling, eventually influencing product integrity and discussion. This misalignment may originate from damaged components or inappropriate setup throughout first installation.

An additional constant problem is inconsistent packaging speeds, commonly triggered by mechanical wear or inadequate maintenance. Variability in rate can cause bottlenecks, creating hold-ups and reducing general productivity. Furthermore, poor training of personnel can aggravate these problems, as drivers might not completely comprehend equipment performances or troubleshooting techniques.

Furthermore, product jams are a common incident, usually due to wrong material specs or international objects blocking the device's path. Such jams can halt production, necessitating instant intervention to get rid of the blockage and return to procedures.

Finally, electronic mistakes, including software problems or sensing unit failures, can impede device capability - packaging machine repair service. These issues need prompt attention, as they can result in extensive downtime if not addressed immediately. Comprehending these typical concerns is essential for maintaining ideal performance and decreasing disruptions in packaging procedures

Diagnostic Techniques for Repairs

Implementing reliable analysis techniques is important for identifying and settling concerns in packaging equipments. A methodical strategy to diagnostics permits specialists to determine the origin of malfunctions efficiently, thus reducing downtime and boosting operational performance.

Among the primary techniques entails visual inspections, where professionals examine the maker for any type of apparent indications of wear, imbalance, or damages. This foundational action can frequently disclose essential issues without the need for advanced tools. Making use of diagnostic software program can substantially enhance the troubleshooting procedure. These devices examine machine performance data, providing understandings right into abnormalities that may not be promptly visible.

An additional necessary method is conducting useful examinations. By methodically operating numerous parts of the device, specialists can observe performance discrepancies, assisting to separate faulty components. Furthermore, applying resonance evaluation and thermal imaging can discover hidden troubles, such as misaligned belts or overheating bearings, which are frequently precursors to much more considerable failures.

Step-by-Step Repair Work Treatments

A comprehensive repair procedure is vital for recovering capability to malfunctioning packaging equipments. The process begins with a detailed evaluation of the problem, making use of analysis techniques to identify the source of the breakdown. Once determined, collect the necessary tools and replacement components to assist in the fixing.

Next, ensure that the device is powered off and separated from its power source to guarantee safety and security during the repair. Recording the equipment's arrangement prior to disassembly can help in reassembly - packaging machine repair service. Very carefully eliminate any covers or panels to access the malfunctioning parts, noting any type of details screws or bolts that need focus

Replace or repair the malfunctioning components according to the supplier's requirements, making sure that all links are safe and secure. After reassembly, carry out an aesthetic examination to validate that all components are appropriately mounted which there are no loose connections.

Once the equipment is reconstructed, reconnect the power and conduct tests to ensure proper performance. Display the equipment throughout procedure to determine any residual problems.

Preventive Maintenance Practices

Maintaining the capability of product packaging makers is not only reliant on responsive repair service treatments; positive preventative upkeep techniques play a significant role in ensuring their longevity and efficiency (packaging machine repair service). By applying a Find Out More structured preventative maintenance program, operators can recognize potential problems before they rise into expensive break downs

Specialists need to routinely check elements such as belts, gears, and sensors for wear and tear. In addition, cleaning up machines to remove dust and debris is important for optimum efficiency and to protect against contamination of items.

Training personnel on appropriate usage and handling of product packaging devices can also lessen the threat of functional mistakes that might cause equipment failing. Establishing an upkeep schedule that includes periodic checks and replacements of critical parts can substantially prolong the life expectancy web of the equipment.

Documenting all upkeep tasks not only help in tracking the wellness of the devices however likewise adheres to regulative requirements. By focusing on preventive upkeep, business can ensure their packaging equipments run at peak efficiency, inevitably enhancing productivity and minimizing downtime.

Tools and Resources for Technicians

Equipping service technicians with the right devices and resources is crucial for efficient packaging maker repair work and maintenance. A well-stocked toolkit needs to consist of accuracy instruments such as calipers, wrenches, and screwdrivers customized for specific machine elements. In addition, analysis devices like oscilloscopes and multimeters allow technicians to determine electrical concerns promptly and precisely.

Moreover, purchasing software application options for devices tracking can boost anticipating upkeep practices. These applications assess device efficiency data, informing professionals to prospective concerns before they rise.

Connecting with peers and joining industry discussion forums can promote expertise sharing and finest methods among professionals, cultivating a collective setting for constant understanding. Last but not least, preserving connections with distributors makes certain fast access to spare components and specialized devices, decreasing downtime during repair work. By leveraging these sources and devices, service technicians can improve their effectiveness and efficiency in keeping optimum efficiency of product packaging equipments.

Verdict

Reliable product packaging maker repair work is essential for preserving functional continuity and product high quality in today's hectic production setting.Product packaging makers, crucial for reliable production lines, commonly come across a number of common concerns that can interfere with operations.An extensive fixing procedure is crucial for recovering capability to malfunctioning packaging makers.Outfitting specialists with the right devices and sources is vital for effective product packaging maker fixing and upkeep.In final thought, efficient product packaging machine fixing techniques are crucial for maintaining optimum efficiency and lessening operational downtime.

Report this page